bursting strength test|rycobel burst strength chart : broker Burst testing is a technique to measure the pressure resistance of materials until they rupture. Learn about different types of burst testing, burst test machines, and burst test standards for various industries and applications. Novinha Gostosa de Shortinho socado. priiscilahot. 2K Visualiz. 91% 1:11. madrasta do rabão gostosa faz faxina usando um shortinho socado no cu. Niah Meskita. 19K .

{plog:ftitle_list}

WEBBenfica TV is Live now, On Air : Benfica 21 Horas. Benfica TV is Airing from Portugal, but you can watch Benfica TV from outside Portugal because this Live Streaming is Not .

Burst testing is a technique to measure the pressure resistance of materials until they rupture. Learn about different types of burst testing, burst test machines, and burst test standards for various industries and applications.

license tests by hardness

When determining the strength of a box, the corrugated box industry uses two test, the Bursting (Mullen) Strength Test and the Edge Crush Test (ECT). The Bursting Test is reported in . (In other word) Fabric bursting strength test is an alternative method of measuring strength in which the material is stressed in all direction at the same time and is therefore more suitable for such material. Example: .The burst test is frequently used as a general guide to the strength of paper, solid board and corrugated board. Bursting strength is usually quoted in kPa. We determine bursting strength using a digital hydraulic paper or digital hydraulic .

rycobel burst strength chart

Learn what bursting strength or burst resistance is and how to measure it with different types of burst testers. Find out the applications and properties of bursting strength for paper, plastic and corrugated board.Burst testing is an essential process in engineering and materials science. Burst testing, also known as burst pressure testing, helps us understand how strong materials and products are. In this article, we will explore why burst testing .

Bursting strength is a function of various processes performed in the papermaking process. The increased use of fillers decreases bursting strength, while the increased use of longer fibers .Pneumatic Bursting Strength Tester with TestWise™ software and a range of bursting strength and fatigue tests suitable for knitted textiles, medical textiles, nonwovens and plastics. In this installment of our Your Questions Answered .This International Standard specifies a method for measuring the bursting strength of paper submitted to increasing hydraulic pressure. It is applicable to paper having bursting strengths .This test, also known as a Mullen Burst Test, is one of the most common material properties test required by carriers and governments. Bursting Strength testing basically measures the force required to puncture through a .

proof pressure vs burst

how to calculate bursting factor

A test piece, placed over a circular elastic diaphragm, is rigidly clamped at the periphery but free to bulge with the diaphragm. Hydraulic fluid is pumped at a constant rate, bulging the diaphragm until the test piece ruptures. The bursting strength of the test piece is the maximum value of the applied hydraulic pressure. 5 Apparatus

Burst strength testing. Burst testing measures the strength of fabrics and materials, by providing pressure (force) on the material from all directions equally at the same time, to measure the conditions that will cause it to rupture. When .

ISO 2759:2014 specifies a method for measuring the bursting strength of board submitted to increasing hydraulic pressure. It is applicable to all types of board (including corrugated and solid fibreboard) having bursting strengths within the range 350 kPa to 5 500 kPa. It is also applicable to papers or boards having bursting strengths as low .

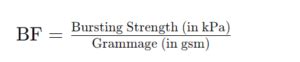

Features of Presto bursting strength tester. This bursting strength tester plays a major role in the paper and packaging industry and helps to measure the strength of these boxes with ease. Thus, to make sure that these boxes will be delivered without any errors, it is important for you to test the bursting strength of these boxes.TAPPI T 807, Bursting strength of linerboard, Test Method [6] TAPPI T 810, Bursting strength of corrugated board, Test Method [7] TAPPI T 1200, Interlaboratory evaluation of test methods to determine TAPPI repeatability and reproducibility [8] Brauns O., Danielsson E., Jordansson L., Svensk Paperstidning 23 867 (1954) 1) [9]A test piece, placed over a circular elastic diaphragm, is rigidly clamped at the periphery but free to bulge with the diaphragm. Hydraulic fluid is pumped at a constant rate, bulging the diaphragm until the test piece ruptures, The bursting strength of the test piece is the maximum value of the applied hydraulic pressure. SamplesBurst factor = Burst Strength (kg/cm2) x 1000/Grammage (gm/m2) To assess this, the package is expanded through the use of a rubber diaphragm or another technique until either the package or its seals rupture. How Do You Test Bursting Strength According to the Standard? To perform a burst test according to the ASME PCC-2 guidelines, there are .

Learn about the burst strength of corrugated boxes & the different ways to test your packaging to ensure quality & durability under different environments. . For this, you can run the Mullen's test (burst tests) to truly test the strength of your packaging. If you do find that your boxes feel a bit flimsy, take them out of your shipping .Pneumatic Bursting Strength Tester for bursting strength and fatigue tests. Suitable for knitted and medical textiles, nonwovens, paper and plastics. Skip to main content Toggle navigation . Test a variety of materials including textiles, nonwovens, plastic bags, food packaging, tissues, tin foil and medical products .

In some standards they advise to use a smaller or bigger dome. Some standards make provision of a sample not bursting. For example in ASTM D3786, it states: If the fabric does not burst, the report should state the maximum bursting pressure of the instrument and that the sample had not burst at that pressure.A bursting test is also known as a Mullen test or pop test, and a minimum bursting strength is required for cartons used for shipping. Bursting strength has little application to printing papers. All text and images are licensed under a Creative Commons License permitting sharing and adaptation with attribution.

The bursting strength tester is the best test machine which is widely used to evaluate the burst strength of the papers and textile materials to make the products burst proof. The instrument offers highly accurate, reliable test results with highly advanced features. Before buying the instrument, one must spend some valuable time in .The burst test determines the maximum resistance (in kPa) of a specimen to an increasing pressure. ZwickRoell burst testers determine the bursting strength of paper in accordance with ISO 2758.The bursting strength of board and paper to ISO 2759 can also be determined with ZwickRoell, thereby covering the entire range from paper to heavy corrugated board.Using the ‘push to burst’ switch to apply the hydraulic pressure on the sample. The pressure is applied via a rubber diaphragm which inflates when hydraulic pressure is increased. The point at which sample burst, the machine notes down the pressure applied. Using this bursting strength, bursting factor and bursting index can be determined.

Bursting strength is measured utilizing a rubber diaphragm that is expanded hydraulically against the paper sample. A bursting test is also known as a Mullen test [New Window] or pop test [New Window], and a minimum bursting strength is required for cartons used for shipping. Bursting strength has little application for printing papers.“ The .

bursting strength tester meaning

The bursting strength of a corrugated sheet can be easily calculated by performing the bursting strength test or the Mullen test. This is the most efficient testing procedure that is designed for testing the bursting .Digital bursting strength tester at best price in India. Get quotation from a top manufacturer and supplier of bursting strength tester / BS testing machine. +91 9313 140 140 . [email protected]. . Test Standards: ASTM D . Since only testing the tensile strength of knitted fabric does not reflect this top breaking strength, so we need to use specific equipment to test the force that the knitted fabric is subjected to when it expands to rupture, this special test fabric top breaking strength or bursting strength of the instrument called the Bursting Strength Tester.Burst Strength Test. To perform a burst strength test, a package is inflated with air until the package seals rupture. The internal pressure of the package at the moment of burst is measured. One technique for conducting a burst test is to otherwise not constrain the package while it is inflating, as described by ASTM F1140. Some large packages .

#1– Bursting Strength Test. WHAT: Test box strength when subjected to pressure; WHY: To determine exact weight a box can carry, rough handling; The Mullen Test or Bursting Strength Test checks the toughness of the walls of the corrugated board when subjected to force or pressure. In this testing procedure, a rubber diaphragm is used to apply .

A fabric bursting strength tester is used to test the bursting strength performance of woven, knitted, and non-woven fabric, paper, or sheet. Thus, we also require more skills and details in daily maintenance. The main engine 1 The fixture equipped in the machine should be coated with anti-rust oil.Edge Crush Test Chart. Below is a chart that breakdowns different types of corrugated material and their corresponding bursting test and ECT rating, along with the maximum load per carton. The 32 ECT, 44 ECT, and 48 ECT are the most common box varieties, due to both cost and stacking strength considerations.Preprogrammed test routines Easy touch screen for running and viewing results PnuBurst Pneumatic Bursting Strength Tester The PnuBurst provides unparalleled capabilities in a pneumatic bursting tester. The full-color touch screen controller is very easy to use and provides full test controls including clamping pressure and Marks & Spencer controls.

Scope1.1 This test method covers measurements of the bursting strength of paper and paper products occurring as single or laminated flat sheets not over 0.6mm. (0.025 in.) in thickness having a bursting strength of 30 kPa up to 1400 kPa (4 psi up to 200 pThe burst test solutions your products deserve. As a global manufacturer of moisture, gas and oxygen analyzers, we have a range of burst test and inspect options available. We can deliver accurate package test results directly to your quality control department – making sure the materials you plan to use deliver the great results you expect. Table of Contents Understanding the ISO 13938 Standard for Textile Bursting Strength Testing The Advantages of Using the Hydraulic Method for Textile Bursting .Since its invention in 1887, the Mullen Burst Tester has been the industry benchmark for measuring the burst strength of paper, paperboard, non-wovens and textiles. What started as an innovative contribution to the paper industry eventually served to define the "standard grades" in commerce. . Test Standards : Find Your Tester : 939 Chicopee .

bursting strength tester

WEB15 de jul. de 2023 · Experimente a emoção de jogar slots de demo da PG Soft gratuitamente em DemoSlotsFun.com. Descubra uma ampla variedade de jogos .

bursting strength test|rycobel burst strength chart